Automatic Power Factor Correction (APFC) Panels are designed to provide unmatched performance, reliability and versatility for critical Power Network applications. All the controllers offer rock-solid control & monitoring, front panel status reporting and control operation combined with Superior design and robust construction We follow 100%; testing that includes the following (Visual and dimensional check. Mechanical operation check, Applied voltage test to earth on power circuits: 3kV for 1 minute, Electrical and functional operational check) after passing a Routine Factory Test (RFT) Certificate is issued with every panel manufactured.

Products & Services

Automatic Power Factor Control (APFC)

Electrical Ratings

• Rating: 100,150, 200,250,300,400, 500,600,750,900, 1200 KVAR (other ratings are available on request)

• Heavy Duty Capacitors Rated 415V, 460V, 480 VAC for extra protection against over voltage

• Self-Healing MKP Dielectric

• Over Pressure Device for the capacitor

• Standard IEC 831-1/2 and IEC 439-1

• Relay current input signal: from CT online

• IP 54 indoor (outdoor ratings also available)

Power Control Centre

Power Control Center is used for distribution and control of various source used in industry. Normally Power Control Center is installed near power source hence fault level is high. Busbar system in Power Control Center are designed to suit the fault level as well as temperature rise to 40 C above ambient. Ample space is provided for cable termination. Various protections viz short circuit, overload, earth fault under voltage etc. are provided to protect source and equipment.

Programable Logic Controller (PLC)

Programmable Logic Controller (PLC) control panels or also known as PLC Automation are one of the most important and efficient kinds of control panels. Which are generally used in variety of electronic and electrical circuit fittings. PLC Control Panels we manufacture are highly capable of giving higher output at less power consumption, integrated with solid PLC Logic and flawless PLC hardware programming. We are engaged in designing and manufacturing of PLC & Automation Panels that is widely appreciated for longer service life and high efficiency. All these panels are hard wired, PLC based and electrically controlled and is used for various machines.

Synchoronization Switchgear Panel

Synchronization Switchgear Panel also referred to as Paralleling Switchgear provides a means to synchronize and parallel multiple generators of same or different sizes make on a common bus. Reliability, Redundancy, Flexibility, Maintainability, Economy are some of the advantages of Synchronization Switchgear. In our Synchronization Switchgear System, each Generator has its own control panel with all required control devices, which works in conjunction with System Master Controls to perform the overall operation of synchronization switchgear system. PLC based controls in conjunction with synchronizer / load sharing control devices makes the system work with no operator intervention. Manual operation – synchronization, speed / voltage control and circuit breaker control are available as option. Analog instrumentation and visual annunciation is optional.

FEATURES:

• Multi-Generator Synchronization Panel

• Automatic and Manual operation PLC based & Synchronization / Load Sharing by controller

• Employs random synchronization, KW / KVAR sharing

• Optimization based on Load vs. Capacity calculations

• Active Load Control – Load Add / Load Shed (KW and Freq.)

• HMI for operator interface to monitor and control

• Multi-User Access – multiple levels with password

• Test function – No-Load, With-Load, Load Banking

• Monitoring – DMM, Generator, Fuel System, ATS etc.

• Communication – Modbus TCP for SCADA / BMS

Power Distribution Board (PDB)

Our Power Distribution Panels are using in application like power distribution, ground-fault protection and monitoring, apart from this Distribution Panel also serves as alarm panel for freeze protection, board temperature-maintenance and heat-tracing applications. These Power Distribution Panels are intergrated with groundfault circuit breakers in an enclosure having assembled circuit-breaker panel board with or without alarms contacts.

VCB Panel

VCB Panel is recognized as the most usable & reliable current interruption technology System for high & medium voltage switchgear. It offers exceptional performance during the restriction of electrical Short Circuit. VCB Indoor panel is used for the protection of Transformer Motor, Capacitor Bank & Power Distribution System. These panels are also customized to suit client specification and requirement.

CORE FEATURES

• Powerful switching and maintenance-free care using Elan Automation internationally recognized vacuum interrupter

• Proven APG encapsulation process ensuring stable operation in harsh environments

• Complete compatibility with the mainstream domestic medium voltage distribution panel KYN28, lowering costs for Chinese users

• Guaranteed interchangeability and universality with all products being subjected to pre-engineering tests for standard panels

• Stable performance proven over hundreds of mechanical operation running in tests on all products before they are delivered

• Proven spring mechanism for stable operation, strong protection against corrosion and a long service life

• Class E2 electrical endurance, class M2 mechanical endurance and class C2 breaking capacitive current as per GB 1984-2003

Motor Control Centre Panel (MCC)

A Motor Control Center (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. Motor control centers are in modern practice a factory assembly of several motor starter. A motor control center include variable frequency drives, programmable controller, and metering and may also to be electrical service entrance for the building.

Motor Control Center have been used by the automobile manufacturing industry which used large number of electric motor. Where very dustry or corrosive processes are used, the motor control center may be installed in a separate air-conditioned room, but often and MCC will be on the factory floor adjacent to the machinery controlled.

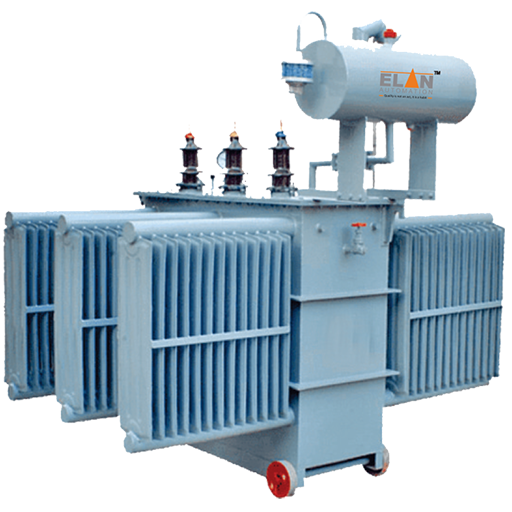

Distribution Transformer

Capacity: 25 KVA to 5000KVA

We are customer-centric organization, therefore offer our clients with excellent quality Distribution Transformer and Servo Voltage Stabilizer that is used to provide safety to electrical equipments during power fluctuation. This transformer and stabilizer are manufactured using quality tested components and progressive techniques under the experts’s supervision.

Compact Substation

The Sub Distribution Panel or Board consists of a basic frame with all the necessary electrical components such as main isolating switches, emergency shut-down mechanism. RCD’s, line circuit breakers, controls and contractors for individual workgroups. The distributor can supply multiple workgroups with electrical power independently. We design and manufacture the Sub Distribution Panel according to the Customer’s need through reliability. Selectivity, durability and time of taking action to Product Quality which comply with cost effective, long life and application-wise.

Automatic Servo Voltage

Capacity: 30 KVA to 4000KVA

Ladder Type Cable Tray

We offer high strength ladder type cable trays that are perfect for heavy-duty power distribution in industries. Ladder cable tray use for the power cables and controls cable in various places in the industries. We offers ladder cable tray with complete accessories for smooth and fast installation. There are two type of ladder cable tray available one is nut bolted type and other is fixed type, we offer both type ladder cable tray. We manufacture ladder cable tray in different material as required by the customer.

We manufacture different material ladder cable tray

• Hot Dip Galvanized Ladder Cable Tray

• Painted ladder cable tray.

• Powder Coated Ladder Cable tray

• Pre Galvanised sheet Ladder cable Tray

Perforated Type Cable Tray

We manufacture the race way for the control cables.The race way cables are covered so that the dust will not deposit on the cable. These covered race ways cables are used in those industry where more dust or other micro particles are present e.g. power plant where coal is pulverise, cement factory etc. Our cable raceway is available in many different materials and installation is simple.

We manufacture different Perforated Cable tray:

Aluminium Cable Tray

• Hot Dip Galvanized Cable Tray

• Painted cable tray

• Powder Coated Cable tray

• Galvanized perforated cable Tray

• Stainless steel Cable tray